ON&T recently caught up with Ted Brockett, one of the pioneers of seabed mining technology, to take a look back at the early days of ocean exploration

The Deepsea is often branded as the next frontier in ocean exploration. We have long known that the seafloor, at depths of up to 6000 m, is home to an abundance of rare-earth elements, such as erbium (Er) and promethium (Pm), as well as other prized metals like nickel and cobalt, and our attention now turns to the viability of mining these materials to build out a sustainable future. The harvesting of polymetallic nodules, while only one method of extraction, increasingly seems to be the most feasible in the short- to mid-term. Currently, exploration activities continue in the Pacific Ocean’s Clarion Clipperton Zone (CCZ), as commercial and state-led entities carry out their environmental due diligence and test their subsea technologies.

The Deepsea is often branded as the next frontier in ocean exploration. We have long known that the seafloor, at depths of up to 6000 m, is home to an abundance of rare-earth elements, such as erbium (Er) and promethium (Pm), as well as other prized metals like nickel and cobalt, and our attention now turns to the viability of mining these materials to build out a sustainable future. The harvesting of polymetallic nodules, while only one method of extraction, increasingly seems to be the most feasible in the short- to mid-term. Currently, exploration activities continue in the Pacific Ocean’s Clarion Clipperton Zone (CCZ), as commercial and state-led entities carry out their environmental due diligence and test their subsea technologies.

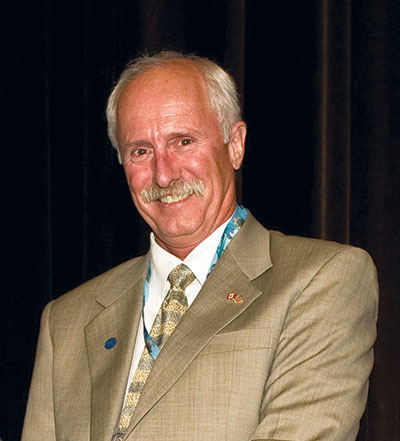

As we assess the viability of full-scale seafloor mining operations there are, perhaps, lessons we can learn from the past. Few people are better placed to comment on the challenges and prospects of ocean mining than Ted Brockett, the managing director of Okeanus Science & Technology. Mr. Brockett’s career stems five decades in the marine mining industry; indeed, he was one of the early pioneers of commercial efforts to harvest nodules from the seabed in the late 1970s.

ON&T: Take us back to the early days, how did you get involved in deep-sea mining?

TB: I studied mechanical engineering as an undergraduate back in the early 1970s. I wasn’t set on any particular career, but I was sure of one thing: I wanted a marine-related future. In fact, it was my love of the ocean—and perhaps the promise of unlimited surfing and diving—that influenced my decision to study a master’s degree in Hawaii, with a focus on corrosive forces.

As is often the case, it was my professor that gave me a timely vocational nudge and introduced me to an outfit called the International Nickel Co. (INCO), which has since been incorporated into the Brazilian metal and mining multinational Vale. That connection paid dividends when I graduated and, on the back of some respectable grades, I was invited to work in their R&D office and so relocated to the Seattle area, which is where I’ve lived since.

ON&T: What did INCO do back then?

TB: The company had a long-established tradition of terrestrial mining but also had a growing interest in offshore exploration, in particular how to harvest what we called “manganese nodules” back then (more commonly referred to as polymetallic nodules today) from the seafloor. To that end, the team had solicited the help of external consultants to develop a passive seabed collector. So, my first job was to put this collector through its paces. We took it out to various test sites and mudflats, but it was an unmitigated disaster. No matter what we did, some part or another of the system would always end up failing. To my mind, a passive design just wasn’t going to get the job done.

We went back to the drawing board and devised something we called Electro-Hydraulic, which we dubbed EH. The system was built around one core distinction: to use ambient seawater to perform all of the collector’s tasks, that is, to collect and clean the nodules of sediment before feeding a riser pipe. This was central to the design process; our objective was to optimize operational efficiency and limit the need for additional power generation at collection. In short, the fewer moving parts on the seabed, the less likelihood of system failure; the less sediment in the riser pipe, the more nodules can be harvested within any given timeframe.

ON&T: Clearly, this is complex engineering for a very specific task. Were there setbacks?

TB: Plenty. This was custom engineering in its purest form. And the stakes were high. So high, in fact, that companies began forming specialist marine mining consortiums in the mid-1970s. INCO led the way with the creation of Ocean Management Inc. (OMI), a joint venture that also incorporated AMR (a German consortium), DOMCO (a Japanese consortium led by the Sumitomo group of companies) and SEDCO (a Texas-based offshore services provider). To mitigate against the growing risks associated with marine mining, the strategy was to divide the exploration and extraction process into critical areas of expertise.

INCO assumed the lead for collector development, which included the responsibility for program management, hydraulic and passive collector development, land-based test facility design and construction, and an at sea collector test program.

ON&T: So, given that there were other consortiums, was there a race to the seafloor, so to speak?

ON&T: So, given that there were other consortiums, was there a race to the seafloor, so to speak?

TB: Yes. There were three others. There was the Kennecott Group, Ocean Mining Associates, and the Lockhead Group, all of which incorporated both American and international companies. I’m not sure I would describe it as a race exactly, but one of the consortiums was always going to be the first to run a successful pilot test in the Pacific, and that was us at OMI.

ON&T: OK, we’ll get to the pilot test, but first, how did you go about designing and engineering failsafe equipment for deployment at such unchartered depths?

TB: Designing machinery for deployment in relatively alien environments requires diligence, patience and flexibility. It’s not just a case of concept testing, but providing evidence of operational efficacy and safety, and that requires rigorous stress testing. Operating at depths of up to 6000 m comes with inherent risks, and mistakes are extremely costly.

Naturally, there are several stages of development, including conceptual design, laboratory testing of key components, detail test design, and test collector fabrication, which our consortium carried out simultaneously in three countries. With validation of concept, comes the need to apply those designs to the field. For the pre in-situ testing we simulated the subsea environments as best as we could by using pools and mud pits. We found suitable substitutes for nodules and sediment and tested a range of passive collectors (Rhombic Rake, Passive Inverted Plow) and active collectors (Electro-Hydraulic, Active Inverted Plow, DOMCO Hydraulic), among others. This allowed us to eliminate certain designs, before boarding the German RV Valdivia in 1976 to run in-situ tests in the Clarion Clipperton Zone (CCZ).

We had a number of systems aboard, but our shortlist for in-situ testing centered around the Electro-Hydraulic, the Active Inverted Plow, the DOMCO Hydraulic, and the Cutter Blade Scraper (CBS) collectors. We weren’t out there to actually collect nodules but rather see how the systems performed in the deep, which often presents the most challenging marine conditions imaginable. Our time offshore in 1976 was invaluable and allowed us to narrow our design focus.

ON&T: What did you learn from the in-situ testing?

TB: That operating in remote locations, and at such depths, is highly unpredictable. There is so much that can go wrong, and mistakes mean setbacks. In fact, while we were out there, we lost the DOMCO collector altogether due to a tow cable failure. But the in-situ testing, more than anything, allowed us to refine our focus and fine-tune two systems: the 2M and 3M Seafloor Collector systems. They were both passively towed two runner sleds that used a straightforward hydraulic design. As the names suggest, one had a two-meter modular active width with a mere 20 HP for all functions and one was three meters wide and supported by 25 HP. They both used a cloth sail to ensure hydrographic stability and safe bottom landing.

ON&T: What was different about these designs?

TB: Well, the key to their design was their simplicity. We adopted the US Navy’s 1960 design principle, K.I.S.S., or Keep It Simple, Stupid. Reliability is the key to operating effectively in the Deepsea, and overengineering solutions is an obvious trap. We persisted with a hydraulic design as we were adamant that seawater—the natural environment—should do the heavy lifting, so to speak, by removing sediment from the nodules, transporting them within the collector, before finally feeding the nodules into the riser pipe. The system was built around a high volume, low pressure flow that sent nodules up a duct to a containment cage and hopper conveyor.

One key aspect of the design was to reject oversize nodules, not only sediment, to prevent riser pipe clogging and guarantee system optimization. There were two points of rejection, first at the dredge heads (materials wider than 3-1/4” prevented from entering) and then behind the discharge of the dredge heads, where materials 2 – 3/16” were rejected downward between runners powered by a slurry flow up ramp.

ON&T: So, when did you actually go from in-situ testing to running a pilot test?

ON&T: So, when did you actually go from in-situ testing to running a pilot test?

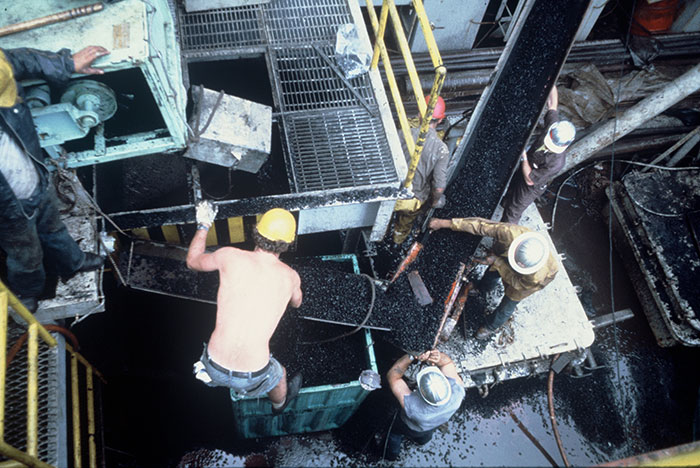

TB: Not until 1978, when we set sail for the CCZ once again aboard the SEDCO 445. Of course, the collectors were just part of a larger system. 1000 HP submersible pump lift systems were manufactured by KSB, two of which were needed for the deployment of 2M (allowing for 40 metric tons per hour), three for 3M (60 metric tons per hour). The pumps connected to a 5,350-meter long riser system and an interface hose.

ON&T: Was the pilot a success?

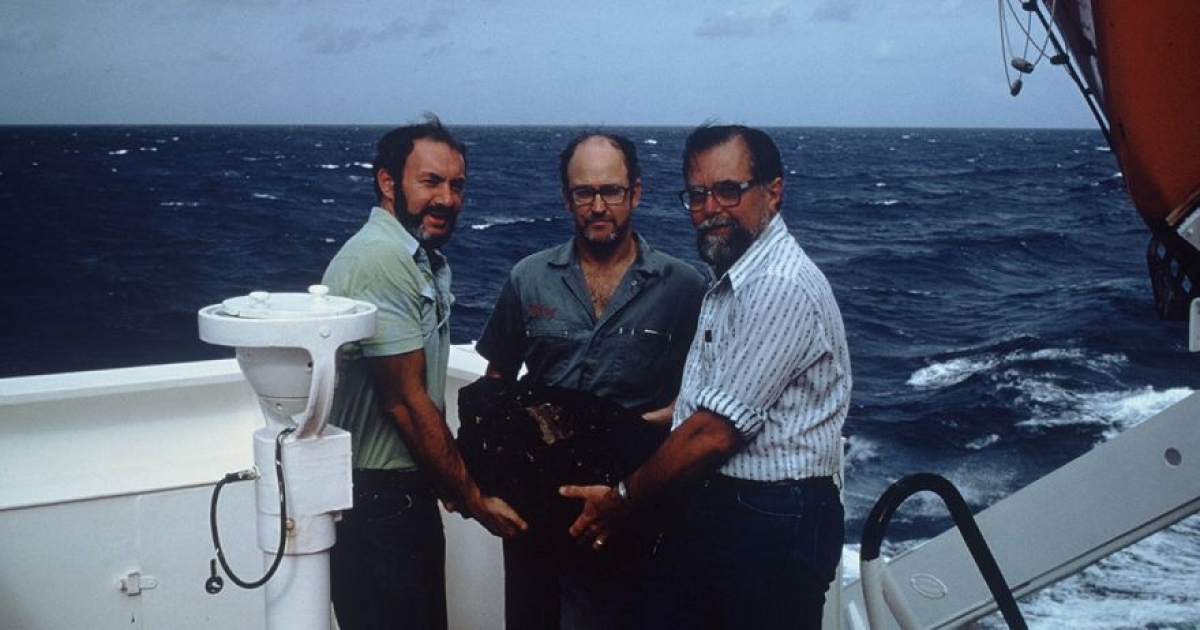

TB: Absolutely. You have to remember; nobody had attempted to mine the Pacific at these depths before. I believe Deep Sea Ventures had run a pilot test on the Atlantic’s Blake Plateau, but at depths of 500 m or so. The CCZ, at depths of over 5,400 m, is another prospect altogether. By measure of success, we were able to collect 1000 tons of polymetallic nodules and the equipment performed as designed. Other pilots followed, run by the other consortiums, but we were the first to mine in this unchartered territory.

ON&T: So, what happened after the pilot?

TB: Somewhat abruptly, management decided to halt operations. Throughout 1978, there was creeping concern surrounding the jurisdiction of exploration activities in the deep Pacific. Developing nations started to question the motives of operators like INCO carrying out pilots in and around their waters. Much of the scrutiny stemmed from an ongoing legal discussion triggered by a speech made by then Maltese ambassador Arvid Pardo to the United Nations in 1967, in which he proposed that the seabed and ocean floor beyond national jurisdiction be considered the “common heritage of mankind”. This gave island nations leverage, a bargaining chip if you will, and they began suggesting that operators wishing to harvest the deep should compensate accordingly and even share their subsea technologies, etc. Mining companies, terrestrial or marine, are notoriously protective of their intellectual property so this was never going to happen.

It did, however, add fuel to the question of governance in international waters and this, of course, culminated in the creation of the “Law of the Sea” and the International Seabed Authority (ISA), in 1982. From an INCO perspective, I think there was more of a concern surrounding the financial viability of establishing ongoing operations. The company had just opened a number of terrestrial mines, so I suspect this was a question of investment priority. Had it been more financially viable, I think we would have found a workaround.

ON&T: What happened to the team?

TB: Some of the team were retained and repurposed, but I left and founded Sound Ocean Systems (SOSI) with other ex-employees. Our first job was with OMI, funnily enough. Our second was for the National Oceanic and Atmospheric Administration (NOAA). NOAA was actually present throughout out pilot test in 1978, aboard their own vessel measuring surface and seabed sediment plumes created by the nodule collection.

ON&T: What happened to the nodules?

TB: They were processed, as far as I understand it. I’m not entirely sure where this was done and by which arm of the consortium, but I do know that upper management at the time were presented with these little IMO-branded ingots of nickel as a memento of our endeavors. I was a little irked at the time not to receive one myself but have since managed to acquire two. I intend to donate one to the ISA Gallery at the organization’s headquarters in Kingston, Jamaica.

ON&T: Today, we are learning so much more about the Deepsea and areas like the CCZ, but back then it must have been surreal to be so isolated and on the brink of discovery. Do you have any enduring memories or reflections of your pilot test?

TB: I have many, of course. Today, with so much activity in the CCZ—and considerable investment—my recommendation for operators is to keep things as “simple” as possible. There are so many variables at play in the deep and you need to understand what you can and cannot control.

From a personal point of view, isolation at sea certainly gives you a fresh outlook on how vast the ocean is. It is hard to describe how I felt, on reflection, because the entire process was so abstract. It had never been done before. But there was something quite bizarre about being days out to sea, on the steel deck of a ship in the searing tropical heat and hearing this faint rattling sound made by the nodules making their way up the riser. They took 20 minutes to reach the surface, their arrival evermore noisy and turbulent. What struck me more than anything, and this is something I will never forget – the nodules were freezing to the touch. Still gives me chills to this day, actually!

Read part two of our exclusive interview series — The Past, Present and Future of Ocean Mining — with Ted Brockett, managing director of Okeanus Science & Technology

This interview was published in Ocean News & Technology's May 2020 Issue

255 Equity Blvd.

Houma, LA 70360, USA

+1 985.346.4666

11989-A FM 529

Houston, TX 77041, USA

+1 713.460.1400